HP3458 - OHMF and DELAY vs APER and NPLC

Moin,

I've been doing some resistance measurements lately and have

run accross a currious problem. I'm measuring a 10kΩ resistance

standard (L&N 4040-B) with my trusty HP3458 (vintage 1989 or 1990,

firmware rev 4.6 haven't gotten around to update yet).

I've noticed that already with 10kΩ the choice of DELAY and

NPLC vs APER makes a huge difference in measurement value.

To quantify that, I run some measurements yesterday.

Before each round, I did let the DMM rest for 5minutes,

then did an ACAL to ensure same starting conditions

and then, immediately after, run the following measurement

script:

$dmm->write(command => "ARANGE ONCE");

$dmm->write(command => "AZERO ONCE");

$dmm->write(command => "TARM HOLD");

$dmm->write(command => "TRIG AUTO");

$dmm->write(command => "NRDGS 1,LINE");

$dmm->write(command => "NDIG 9");

$dmm->write(command => "OCOMP ON");

$dmm->write(command => "NPLC $nplc") if $nplc != 0;

$dmm->write(command => "APER $aper") if $aper != 0;

$dmm->write(command => "DELAY $delay");

$dmm->write(command => "OHMF");

if($aper != 0)

{

$sleep = ($aper + $delay) * 4 + 2.25;

} else {

switch($delay)

{

case "5e-1" { $sleep = $nplc * 0.1295 + 0.775 }

case 1 { $sleep = $nplc * 0.23945 + 0.2825; }

case 2 { $sleep = $nplc * 0.422525 + 3.11125 }

case 3 { $sleep = $nplc * 0.614 + 5.5 }

}

}

$dmm->write(command => "TARM SGL,1");

usleep(2* $sleep * 1e6);

for($i = 0; $i < 210; $i++)

{

$ohmf = $dmm->get_value();

# throw away first 10 measurments as they have too much bias

$stat->add_data($ohmf) unless $i < 10;

$dmm->write(command => "TARM SGL,1");

usleep($sleep * 1e6);

}

Note that I throw away the first 10 measurements to avoid bias

due to initial settling. The first measurement was low by

0.2ppm to 3.9ppm versus the calculated average, APER almost

an order of magnitude worse then NPLC.

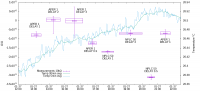

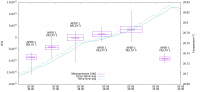

The attached graph is the result of this measurement.

(normalized to APER 1 DELAY 3)

Each box is the average of 200 measurement. The inner box shows

the uncertainty of the center point (3 sigma, width w/o meaning).

The outer box shows the "noise" of each individual measurement

(1 sigma) and the time span over which the whole measurement took

place. The whiskers show the maximum and minimum of the values

used.

The whole setup is in free air in an office, so the temperature

varies a bit. I whish it would have been more stable, but a

maximum deviation of less than 0.17°C over 9h is IMHO acceptable.

The temperature plots are the 5minutes and 30 minutes moving

averages, right next to the resistor (using a BME280).

The first and the last measurement use the same settings for

cross checking. First and last measurement are off by +0.97ppm.

You can find the measured and calulated values down below.

Now, what's curious is, that, although all measurements measured

for the same amount of time (50NPLC = 1s), the noise levels are

quite different. There is approximately a factor of sqrt(5) in

between, suggesting that the measurement is limited by the

sample noise of the ADC and not by some input related noise

(either from the signal or from the integration stage of the ADC).

The second thing to notice is that NPLC 50 DELAY 2 is still

off by -7ppm, compared to APER 1 DELAY 2 and APER 1 DELAY 3.

Which would suggest, that even a 2s delay is not enough for the

system to fully settle.

Now, the big question is, what to use for measurements?

APER has definitely less bias, but has much worse noise.

Yet, I am not sure how large the bias is (it's definitely

still non-zero).

I'm sure I am not the first one to attempt this kind of

measurement with an HP3458. And someone must have gotten

sub-ppm precision with it, otherwise the specs for accuracy

wouldn't be in the 2+0.2ppm range (24h after cal).

So, what are other people doing and how do they achieve

the spec'ed accuracy?

Attila Kinali

NPLC 0

APER 1

DELAY 1

Average: 10000.3894693035

STD-DEV: 0.00695488039639252

Min: 10000.37384

Max: 10000.4097

NPLC 0

APER 1

DELAY 2

Average: 10000.4733173134

STD-DEV: 0.0101684497040978

Min: 10000.39685

Max: 10000.49339

NPLC 0

APER 1

DELAY 3

Average: 10000.4681456219

STD-DEV: 0.0125243902670948

Min: 10000.37739

Max: 10000.54444

NPLC 0

APER 1

DELAY 5e-1

Average: 10000.3451104478

STD-DEV: 0.00706507704987731

Min: 10000.32884

Max: 10000.3677

NPLC 50

APER 0

DELAY 1

Average: 10000.2979074129

STD-DEV: 0.00363564657597388

Min: 10000.28872

Max: 10000.30701

NPLC 50

APER 0

DELAY 2

Average: 10000.3982425871

STD-DEV: 0.00482583949242416

Min: 10000.38485

Max: 10000.41723

NPLC 50

APER 0

DELAY 5e-1

Average: 10000.1577926866

STD-DEV: 0.00359873550247818

Min: 10000.14333

Max: 10000.17091

NPLC 0

APER 1

DELAY 1

Average: 10000.399188607

STD-DEV: 0.00790352248839778

Min: 10000.37715

Max: 10000.41973

--

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto

Good evening!

I had a short discussion with Brooke and it seems like there are

a few more explanations required as to why I am doing what.

So I would like to give a quick run-down of the setup and settings

I'm using.

First of all. The setup is pretty simple and standard. An HP3458

with 4-wire, Kelvin connected measurement of a 10kΩ old resistance

standard made from manganin wire. As far as I am aware of, their

construction follows the one introduced by Thomas in 1930[1]

and later picked up by HP[2]. These resistors usually have a

temperature coefficient in the order of 10ppm/°C at 23°C that

goes to zero around 40-50°C. I do not have enough measurements

to get a number on the TC of this particular resistor, but

it seems to be in the ballpark.

My lead wires are Pomona 5295 type low-emf spade-banana test leads.

I suspended them in air, rather crudely, to ensure they are well

thermalized and that they don't couple anything via the metal

bits fo the table. Twisting the positive and negative leads

together didn't have any significant effect on measurement

performance, so I left them straight, with distance between

each other to minimize capacitive coupling and potential dielectric

absorption. The test leads are not the most optimal, as they

have a PVC insulation which has some dielectric absorption and

might be the cause of what I am seeing.

Now for the settings/script

As I wrote before, before the measurement runs, I frist

do an ACAL.

On Fri, 28 Jan 2022 12:17:00 +0100

Attila Kinali attila@kinali.ch wrote:

$dmm->write(command => "ARANGE ONCE");

I am planing to use the script with different

resistors, so I want the range to adjust to that.

The HP3458 does this by doing a short measurement first.

As I am not changing the resistor once the measurement

started, I only want the DMM to do that once and keep the

setting afterwards.

$dmm->write(command => "AZERO ONCE");

AZERO does calibrate the zero point of the voltage measurements.

There are people on the net who say that this is note required

for OHM/OHMF measurment as OCOMP takes care of that, the user

manual is quite clear that it's required:

Autozero should be on for 4-wire ohms measurements. If you must disable

autozero, be sure to make all measurement connections before disabling

autozero and ensure that the lead resistance will not change. If you disable

autozero before making the 4-wire connections, or if you have a varying lead

resistance with autozero disabled (such as when scanning), you will get

inaccurate 4-wire ohms measurements.

As AZERO doubles the time a measurement takes, I do it only once

and hope that the zero point doesn't move too much during the

measurement. This is a potential source of error.

$dmm->write(command => "TARM HOLD");

Disable arming of the DMM for now. We will later arm

it manually.

$dmm->write(command => "TRIG AUTO");

Set to trigger automatically.

This could be potentially set to TRIG LINE, which triggers at

the zero crossing of mains voltage.

$dmm->write(command => "NRDGS 1,LINE");

Do only one measurement, initiate at zero crossing of mains voltage.

I guess that setting here LINE is enough and I don't need to do

the same for TRIG.

$dmm->write(command => "NDIG 9");

Return all the digits the DMM calculates internally.

$dmm->write(command => "OCOMP ON");

Set offset compensation for OHM/OHMF measurement on.

This does a zero-current measurement first, to measure

the offset voltage to later subtract.

From the manual:

With offset compensation enabled, the multimeter measures the external offset

voltage (with the ohms current source shut off) before each resistance reading

and subtracts the offset from the following reading. This prevents the offset

voltage from affecting the resistance reading, but it doubles the time required

per reading.

$dmm->write(command => "NPLC $nplc") if $nplc != 0;

$dmm->write(command => "APER $aper") if $aper != 0;

$dmm->write(command => "DELAY $delay");

Set the number of line cycles to measure, the aperture period

and the delay before the measurement for the system to settle.

NPLC and APER are exclusive and one disables the other. IF NPLC

is used and it is set to higher than 10, then the measurement is

broken up into pieces of 10NPLC measurements that are then

internally averaged. But, keep in mind that OCOMP, AZERO and DELAY

are all applied to each measurement. I.e. setting NPLC to 50 means

that it's 5×( (10NPLC + DELAY) + (10NPLC for OCOMP + DELAY) )

If AZERO is set, then this doubles as an zero measurement is

inserted infront of each of them.

If APER is used then this becomes ( (APER + DELAY) + (APER for OCOMP

- DELAY) ). Again, if AZERO is set, this doubles.

Keep in mind that the processor has to do some bookkeeping and

calculation after each measurement, which can take a lot of time.

E.g. for the APER case, it's an additional ~2.2s. For the NPLC

case, there seems to be a non-linear relationship between how long

the measurement takes and how long DELAY is. I have not figured

out what is exactly going on there. For a fixed DELAY setting, it

seems to be pretty linear, though.

$dmm->write(command => "OHMF");

Last but not least, set to 4-wire resistance measurement.

$dmm->write(command => "TARM SGL,1");

The measurement is then started by manually arming the HP3458.

The measurement data is later collected, after waiting the

approriate time and another TARM SGL,1 is sent.

To reiterate, what is puzzling me is that I see quite large

settling times, in the multiple seconds range. So much that

using NPLC becomes infeasible because of the long time it takes.

Using APER on the other hand, has the disadvantage of increased

noise and uncertainty.

So I am at the level, where I have to say that I have a measurement

uncertainty of somewhere in the order of 2-10ppm (depending on

how one judges the uncertainty), which is beyond what the HP3458

should be able to do, to reach the specified 2+0.2ppm accuracy

for the 10kΩ range. I am pretty sure that I am doing something

wrong or that there is something I didn't account for. But I

do not know what. And help or advice would be appreciated.

Attila Kinali

[1] "A New Design of Precision Resistance Standard",

by James L. Thomas, 1930

[2] "An Adjustable Standard Resistor with Improved Accuracy

and High Stability", by Hubbs and Hetzel, HP Journal April 1966

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto

I'm not familiar with the 3458A, so don't know how the connections are

made up front. Presuming it's working right, I would suspect the

interconnect setup. The thermal voltages and contact noise may be the

main problem, especially using any sort of banana plugs. If the 3458A's

terminals are the classic 5-way binding posts (likely special low

thermal version), then do away with all banana connections, and use

copper wire directly anchored to the posts - same for the resistor end.

A very convenient way is to use plain two-lead "zip" cord, like on lamps

and small appliances. Be sure it's all copper (not tinned or plated),

and don't tin the ends - just wrap the strands together tightly, and

attach to the posts by wrap-around or through the cross-holes. Put the

source current and high sense on one piece, and the low source and sense

on the other. In operation, the Kelvin connections tie each twin lead

pair together at the resistor, so even crappy insulation won't matter.

Before changing anything around, a little experiment may shed some

light. Instead of doing resistance measurements, set it to measure the

voltage on the resistor, leaving the whole setup as it was. In the most

sensitive ranges, with all those digits, I'd think you'll see the

effects of the input bias current, the thermal voltages, and some

resistor noise. The thermals should be easy to spot - just puff some air

at the connections, or wave your hand around.

Then do the same after you change it to direct wiring. It should be much

better. If not, then that's not the issue. Good luck.

One last thing is to see if there are any strong HF/RF interference

signals available nearby, that could be messing it up.

Ed

On 1/28/2022 12:46 PM, Attila Kinali wrote:

Good evening!

I had a short discussion with Brooke and it seems like there are

a few more explanations required as to why I am doing what.

So I would like to give a quick run-down of the setup and settings

I'm using.

First of all. The setup is pretty simple and standard. An HP3458

with 4-wire, Kelvin connected measurement of a 10kΩ old resistance

standard made from manganin wire. As far as I am aware of, their

construction follows the one introduced by Thomas in 1930[1]

and later picked up by HP[2]. These resistors usually have a

temperature coefficient in the order of 10ppm/°C at 23°C that

goes to zero around 40-50°C. I do not have enough measurements

to get a number on the TC of this particular resistor, but

it seems to be in the ballpark.

My lead wires are Pomona 5295 type low-emf spade-banana test leads.

I suspended them in air, rather crudely, to ensure they are well

thermalized and that they don't couple anything via the metal

bits fo the table. Twisting the positive and negative leads

together didn't have any significant effect on measurement

performance, so I left them straight, with distance between

each other to minimize capacitive coupling and potential dielectric

absorption. The test leads are not the most optimal, as they

have a PVC insulation which has some dielectric absorption and

might be the cause of what I am seeing.

Now for the settings/script

As I wrote before, before the measurement runs, I frist

do an ACAL.

On Fri, 28 Jan 2022 12:17:00 +0100

Attila Kinali attila@kinali.ch wrote:

$dmm->write(command => "ARANGE ONCE");

I am planing to use the script with different

resistors, so I want the range to adjust to that.

The HP3458 does this by doing a short measurement first.

As I am not changing the resistor once the measurement

started, I only want the DMM to do that once and keep the

setting afterwards.

$dmm->write(command => "AZERO ONCE");

AZERO does calibrate the zero point of the voltage measurements.

There are people on the net who say that this is note required

for OHM/OHMF measurment as OCOMP takes care of that, the user

manual is quite clear that it's required:

Autozero should be on for 4-wire ohms measurements. If you must disable

autozero, be sure to make all measurement connections before disabling

autozero and ensure that the lead resistance will not change. If you disable

autozero before making the 4-wire connections, or if you have a varying lead

resistance with autozero disabled (such as when scanning), you will get

inaccurate 4-wire ohms measurements.

As AZERO doubles the time a measurement takes, I do it only once

and hope that the zero point doesn't move too much during the

measurement. This is a potential source of error.

$dmm->write(command => "TARM HOLD");

Disable arming of the DMM for now. We will later arm

it manually.

$dmm->write(command => "TRIG AUTO");

Set to trigger automatically.

This could be potentially set to TRIG LINE, which triggers at

the zero crossing of mains voltage.

$dmm->write(command => "NRDGS 1,LINE");

Do only one measurement, initiate at zero crossing of mains voltage.

I guess that setting here LINE is enough and I don't need to do

the same for TRIG.

$dmm->write(command => "NDIG 9");

Return all the digits the DMM calculates internally.

$dmm->write(command => "OCOMP ON");

Set offset compensation for OHM/OHMF measurement on.

This does a zero-current measurement first, to measure

the offset voltage to later subtract.

From the manual:

With offset compensation enabled, the multimeter measures the external offset

voltage (with the ohms current source shut off) before each resistance reading

and subtracts the offset from the following reading. This prevents the offset

voltage from affecting the resistance reading, but it doubles the time required

per reading.

$dmm->write(command => "NPLC $nplc") if $nplc != 0;

$dmm->write(command => "APER $aper") if $aper != 0;

$dmm->write(command => "DELAY $delay");

Set the number of line cycles to measure, the aperture period

and the delay before the measurement for the system to settle.

NPLC and APER are exclusive and one disables the other. IF NPLC

is used and it is set to higher than 10, then the measurement is

broken up into pieces of 10NPLC measurements that are then

internally averaged. But, keep in mind that OCOMP, AZERO and DELAY

are all applied to each measurement. I.e. setting NPLC to 50 means

that it's 5×( (10NPLC + DELAY) + (10NPLC for OCOMP + DELAY) )

If AZERO is set, then this doubles as an zero measurement is

inserted infront of each of them.

If APER is used then this becomes ( (APER + DELAY) + (APER for OCOMP

- DELAY) ). Again, if AZERO is set, this doubles.

Keep in mind that the processor has to do some bookkeeping and

calculation after each measurement, which can take a lot of time.

E.g. for the APER case, it's an additional ~2.2s. For the NPLC

case, there seems to be a non-linear relationship between how long

the measurement takes and how long DELAY is. I have not figured

out what is exactly going on there. For a fixed DELAY setting, it

seems to be pretty linear, though.

$dmm->write(command => "OHMF");

Last but not least, set to 4-wire resistance measurement.

$dmm->write(command => "TARM SGL,1");

The measurement is then started by manually arming the HP3458.

The measurement data is later collected, after waiting the

approriate time and another TARM SGL,1 is sent.

To reiterate, what is puzzling me is that I see quite large

settling times, in the multiple seconds range. So much that

using NPLC becomes infeasible because of the long time it takes.

Using APER on the other hand, has the disadvantage of increased

noise and uncertainty.

So I am at the level, where I have to say that I have a measurement

uncertainty of somewhere in the order of 2-10ppm (depending on

how one judges the uncertainty), which is beyond what the HP3458

should be able to do, to reach the specified 2+0.2ppm accuracy

for the 10kΩ range. I am pretty sure that I am doing something

wrong or that there is something I didn't account for. But I

do not know what. And help or advice would be appreciated.

Attila Kinali

[1] "A New Design of Precision Resistance Standard",

by James L. Thomas, 1930

[2] "An Adjustable Standard Resistor with Improved Accuracy

and High Stability", by Hubbs and Hetzel, HP Journal April 1966

Hello Attila,

First off, are you confident that your 3458A is properly working and has no stability issues due to A3 U180 drift? It's worth to check that, before you dig deep into sub-ppm rabbit hole. To test for drift issue you can follow SN18 procedure using ACAL DCV daily for a week or two or log known good 10V standard without doing any ACALs over a week or two. Either method should give you good dataset to confirm or deny 3458As stability, which should be better than 0.05ppm/day after correction for temperature.

As for your APER vs NPLC timings and noise. Keep in mind that when you select NPLC larger than 10 meter internally configure ADC to perform not single but multiple conversions with max NPLC 10, and then average out readings before giving to user. So running NPLC 100 (typical sweetspot for 3458s) meaning that meter makes 10 internal readings and give you average of those as result. OCOMP and Delay is also applied after -each- reading, so you get longer than expected acquisition times.

I join the suggestion to ditch banana connectors altogether and use direct spade to post wiring. Also length of wire and insulation matters , so best to keep wires short and PTFE isolated. Other than fancy PTFE wiring, many get good results with shielded UTP (RJ45 cat6, etc) cable with solid copper core. For 10kohm PTFE isn't really that super important but nice to invest into decent cables for future anyway.

What is more important - make sure all connections are clean of any oxides or oils. Oxidized surfaces are unpredictable for thermal EMFs and contact quality. Hence another benefit of binding posts and spades, while turning the nut metal surfaces at the binding posts will scrape thin oxides away and make more reliable metal to metal interface.

Do you have any timescale data plots or CSV files with your setup? You should see flat nice and steady data with specified meters noise, without random jumps or excessive noise. If there is large slope over time, then its good idea to check temperature stability. If your resistor has 10ppm/K TCR then to get 1ppm stability you must maintain environment within ±0.05C. That is not trivial without airbath chamber on any decently long timescale (hours).

I have found some old test with 3458A with 10kOhm measurement, while ambient temperature allowed to go crazy:

https://xdevs.com/sl935_10k_sep/

One can see that loosing 10ppm due to temperature excursions is not hard at all, even with <0.1ppm/K resistance standard (Fluke SL935 has internal oven for resistor elements).

If you have another more stable standard, that would be good alternate check. Sometimes these decades long standards go bad too (from user abuse or mishandling) and become unstable no matter what.

It's been a while since I used 3458s for resistance measurements, as it is not the strongest field for these meters but had no problems with them meeting specifications. I can hook up some resistors and log for you this weekend if you need a reference. Don't have 4040-10kOhm however, sorry.

BR,

Illya

xDevs.com

On January 28, 2022 3:46:41 PM EST, Attila Kinali attila@kinali.ch wrote:

Good evening!

I had a short discussion with Brooke and it seems like there are

a few more explanations required as to why I am doing what.

So I would like to give a quick run-down of the setup and settings

I'm using.

First of all. The setup is pretty simple and standard. An HP3458

with 4-wire, Kelvin connected measurement of a 10kΩ old resistance

standard made from manganin wire. As far as I am aware of, their

construction follows the one introduced by Thomas in 1930[1]

and later picked up by HP[2]. These resistors usually have a

temperature coefficient in the order of 10ppm/°C at 23°C that

goes to zero around 40-50°C. I do not have enough measurements

to get a number on the TC of this particular resistor, but

it seems to be in the ballpark.

My lead wires are Pomona 5295 type low-emf spade-banana test leads.

I suspended them in air, rather crudely, to ensure they are well

thermalized and that they don't couple anything via the metal

bits fo the table. Twisting the positive and negative leads

together didn't have any significant effect on measurement

performance, so I left them straight, with distance between

each other to minimize capacitive coupling and potential dielectric

absorption. The test leads are not the most optimal, as they

have a PVC insulation which has some dielectric absorption and

might be the cause of what I am seeing.

Now for the settings/script

As I wrote before, before the measurement runs, I frist

do an ACAL.

On Fri, 28 Jan 2022 12:17:00 +0100

Attila Kinali attila@kinali.ch wrote:

$dmm->write(command => "ARANGE ONCE");

I am planing to use the script with different

resistors, so I want the range to adjust to that.

The HP3458 does this by doing a short measurement first.

As I am not changing the resistor once the measurement

started, I only want the DMM to do that once and keep the

setting afterwards.

$dmm->write(command => "AZERO ONCE");

AZERO does calibrate the zero point of the voltage measurements.

There are people on the net who say that this is note required

for OHM/OHMF measurment as OCOMP takes care of that, the user

manual is quite clear that it's required:

Autozero should be on for 4-wire ohms measurements. If you must disable

autozero, be sure to make all measurement connections before disabling

autozero and ensure that the lead resistance will not change. If you disable

autozero before making the 4-wire connections, or if you have a varying lead

resistance with autozero disabled (such as when scanning), you will get

inaccurate 4-wire ohms measurements.

As AZERO doubles the time a measurement takes, I do it only once

and hope that the zero point doesn't move too much during the

measurement. This is a potential source of error.

$dmm->write(command => "TARM HOLD");

Disable arming of the DMM for now. We will later arm

it manually.

$dmm->write(command => "TRIG AUTO");

Set to trigger automatically.

This could be potentially set to TRIG LINE, which triggers at

the zero crossing of mains voltage.

$dmm->write(command => "NRDGS 1,LINE");

Do only one measurement, initiate at zero crossing of mains voltage.

I guess that setting here LINE is enough and I don't need to do

the same for TRIG.

$dmm->write(command => "NDIG 9");

Return all the digits the DMM calculates internally.

$dmm->write(command => "OCOMP ON");

Set offset compensation for OHM/OHMF measurement on.

This does a zero-current measurement first, to measure

the offset voltage to later subtract.

From the manual:

With offset compensation enabled, the multimeter measures the external offset

voltage (with the ohms current source shut off) before each resistance reading

and subtracts the offset from the following reading. This prevents the offset

voltage from affecting the resistance reading, but it doubles the time required

per reading.

$dmm->write(command => "NPLC $nplc") if $nplc != 0;

$dmm->write(command => "APER $aper") if $aper != 0;

$dmm->write(command => "DELAY $delay");

Set the number of line cycles to measure, the aperture period

and the delay before the measurement for the system to settle.

NPLC and APER are exclusive and one disables the other. IF NPLC

is used and it is set to higher than 10, then the measurement is

broken up into pieces of 10NPLC measurements that are then

internally averaged. But, keep in mind that OCOMP, AZERO and DELAY

are all applied to each measurement. I.e. setting NPLC to 50 means

that it's 5×( (10NPLC + DELAY) + (10NPLC for OCOMP + DELAY) )

If AZERO is set, then this doubles as an zero measurement is

inserted infront of each of them.

If APER is used then this becomes ( (APER + DELAY) + (APER for OCOMP

- DELAY) ). Again, if AZERO is set, this doubles.

Keep in mind that the processor has to do some bookkeeping and

calculation after each measurement, which can take a lot of time.

E.g. for the APER case, it's an additional ~2.2s. For the NPLC

case, there seems to be a non-linear relationship between how long

the measurement takes and how long DELAY is. I have not figured

out what is exactly going on there. For a fixed DELAY setting, it

seems to be pretty linear, though.

$dmm->write(command => "OHMF");

Last but not least, set to 4-wire resistance measurement.

$dmm->write(command => "TARM SGL,1");

The measurement is then started by manually arming the HP3458.

The measurement data is later collected, after waiting the

approriate time and another TARM SGL,1 is sent.

To reiterate, what is puzzling me is that I see quite large

settling times, in the multiple seconds range. So much that

using NPLC becomes infeasible because of the long time it takes.

Using APER on the other hand, has the disadvantage of increased

noise and uncertainty.

So I am at the level, where I have to say that I have a measurement

uncertainty of somewhere in the order of 2-10ppm (depending on

how one judges the uncertainty), which is beyond what the HP3458

should be able to do, to reach the specified 2+0.2ppm accuracy

for the 10kΩ range. I am pretty sure that I am doing something

wrong or that there is something I didn't account for. But I

do not know what. And help or advice would be appreciated.

Attila Kinali

[1] "A New Design of Precision Resistance Standard",

by James L. Thomas, 1930

[2] "An Adjustable Standard Resistor with Improved Accuracy

and High Stability", by Hubbs and Hetzel, HP Journal April 1966

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto

volt-nuts mailing list -- volt-nuts@lists.febo.com -- To unsubscribe send an email to volt-nuts-leave@lists.febo.com

To unsubscribe, go to and follow the instructions there.

BR,

Illya Tsemenko

Hoi Ed,

On Fri, 28 Jan 2022 15:02:46 -0800

ed breya eb@telight.com wrote:

I'm not familiar with the 3458A, so don't know how the connections are

made up front. Presuming it's working right, I would suspect the

interconnect setup. The thermal voltages and contact noise may be the

main problem, especially using any sort of banana plugs.

These are not "any sort" of banana plugs. These are low-EMF from Pomona.

I doubt that wires would perform significantly better. But it's worth

a shot.

Put the

source current and high sense on one piece, and the low source and sense

on the other. In operation, the Kelvin connections tie each twin lead

pair together at the resistor, so even crappy insulation won't matter.

This I doubt. The effect I am seeing looks awfully like what I would

expect from a settling effect that takes a few seconds. And dielectric

absorption is one of those that are exactly in that time-range.

Before changing anything around, a little experiment may shed some

light. Instead of doing resistance measurements, set it to measure the

voltage on the resistor, leaving the whole setup as it was. In the most

sensitive ranges, with all those digits, I'd think you'll see the

effects of the input bias current, the thermal voltages, and some

resistor noise. The thermals should be easy to spot - just puff some air

at the connections, or wave your hand around.

That's a good idea. I'll set it up next.

Attila Kinali

--

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto

Hoi Illya,

On Fri, 28 Jan 2022 20:22:56 -0500

Illya Tsemenko illya@xdevs.com wrote:

First off, are you confident that your 3458A is properly working and has no stability

issues due to A3 U180 drift?

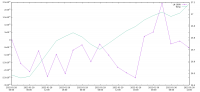

Yes. My meter has not been in use for quite long, so first thing I did was monitor

what CAL 72 did. As you can see from the first plot, it took about half a year of

continuous running until it settled. Since new year, CAL72 has moved up by a ppm.

So I guess that the ADC board is ok.

As for your APER vs NPLC timings and noise. Keep in mind that when you select NPLC larger

than 10 meter internally configure ADC to perform not single but multiple conversions

with max NPLC 10, and then average out readings before giving to user. So running NPLC

100 (typical sweetspot for 3458s) meaning that meter makes 10 internal readings and give

you average of those as result. OCOMP and Delay is also applied after -each- reading, so

you get longer than expected acquisition times.

Yes. I know. That's what explains the sqrt(5) difference in noise between APER 1 and

NPLC 50. That also explains why NPLC is more succeptible to the settling I see than

APER is, because NPLC switches every 200ms. I.e. if the settling isn't over after DELAY,

NPLC will see the residue, while APER will give it an other 800ms to settle and give

the average over that period.

I join the suggestion to ditch banana connectors altogether and use direct spade to post > wiring.

I am not convinced that it's EMF. At least not caused by the cables.

I measured an 100Ω resistor earlier and it did not show anything like this

(measured with NPLC 100, OCOMP OFF, AZERO On and whatever the default DELAY is).

If anything, if EMF was a problem it should be 10 times worse with 100Ω as

the voltage applied to the resistor is 1/10th than with 10kΩ. But as you can

see from the first plot, the 100Ω shows only the ~6.7ppm/°C tempco I would expect it to.

And once this tempco is removed, the combined temperature correction and measurement

uncertainty is about 0.5ppm.

Meanwhile, the 10kΩ (measured with APER 1, DELAY 2, OCOMP On AZERO Once) shows jumps

of >1ppm between measurements. So much that, with the little data I have, I wouldn't

even attempt to calculate a temperature coefficient. The cables are the same, so

the EMF should have the same effect (with the excpetion of the resistor side, that

is now of course different).

My guess is, that most of this uncertainty is from the settling I am seeing, which

I can't really figure out. I think it is dielectric absorption, but I am not sure.

Unfortunately, I don't have PTFE cables at hand.

Do you have any timescale data plots or CSV files with your setup? You should see flat

nice and steady data with specified meters noise, without random jumps or excessive

noise. If there is large slope over time, then its good idea to check temperature

stability. If your resistor has 10ppm/K TCR then to get 1ppm stability you must maintain

environment within ±0.05C. That is not trivial without airbath chamber on any decently

long timescale (hours).

Yes. I looked at the 200 measurements of each run and they are, up to noise, flat.

The noise is also pretty well Gauss distributed, at least for the 100Ω case. For

the 10kΩ case I see a slight e^-t slope at the beginning, but only if I correlate

multiple measurements together, Otherwise it's below the noise. (With APER 1 DELAY 2)

I have found some old test with 3458A with 10kOhm measurement, while ambient temperature allowed to go crazy:

https://xdevs.com/sl935_10k_sep/

One can see that loosing 10ppm due to temperature excursions is not hard at all, even with <0.1ppm/K resistance standard (Fluke SL935 has internal oven for resistor elements).

Ah.. Ok. So you have some effects. But at least it seems to be mostly temperature related.

Your noise is about a factor 10 below what I see and is where I would expect it to be.

If you have another more stable standard, that would be good alternate check. Sometimes

these decades long standards go bad too (from user abuse or mishandling) and become

unstable no matter what.

Unfortunately not a 10kΩ standard only a 100Ω and a 1kΩ. I will see what these show

with the new settings I have.

Attila Kinali

--

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto

Hi Attila,

Yes, those are very nice cables - I looked them up. But, they are still

banana plugs, relying on spring contact. From the description, I'd guess

there are two contacts in series - one from the plug core to the banana

or basket spring, and the other from there to the inner surface of the

jack. Another type is machined directly from springy material, with

cross cuts, and profiled to compress on insertion - these have only one

contact involved, so can be the best of the banana plug class. The fancy

materials and plating help greatly with contact issues, but may still

not be enough. I didn't see any specs on the datasheet other than "low

EMF," so I wonder if maybe they offer related low EMF jack/binding posts

too. Maybe the combination is specified with numbers. Also, what does HP

say in the 3458A manual about interconnect and fixturing?

Regarding dielectric absorption, what is the reference node? If you

connect the wire pairs at the resistor, there is very low resistance and

voltage drop between them at the "open" (3458A) end, so I would think

the insulation between them shouldn't matter too much. The other part of

dielectric absorption would be from each wire pair to the other, and to

everything else beyond. This should be dominated mostly by very small

(due to distance of separation) air capacitance, in series with the the

C from the conductors to the insulation/air boundary. I suppose that you

may be at the resolution level where the effects are noticeable, but my

gut feel is that the wire insulation characteristics are still minute in

scale. The main thing is to maximize the distance between the wire

pairs, and to everything else.

It appears the measuring process includes AC, with the various auto-cals

and zeroing going on, so the resistor and wiring would be jumping to

different voltages in the process. Is it possible to just set up for

pure DC, with constant current in the resistor? This may help to

separate the capacitive from DC effects. Speaking of timing, as you

noted, the few seconds of effects are about right for dielectric

absorption, but also a good profile for thermal or contact effects too.

Especially if the test current to the resistor is being turned on and

off during the process, everything may respond over some time span in

seconds.

One last thing occurred to me. DMMs typically have a switch or post to

connect the low input (guard) to earth ground. Have you tried different

settings for this? I would think grounded should be best, but maybe not.

Maybe you have some subtle ground loops in the system, that could add DC

offsets or AC from the activity. If the grounding choice makes a

difference, check the CMRR specs. That invokes one more last, last thing

- the DUT itself. I don't know what it looks like, but I'd guess it's in

a metal can. If so, there's of course parasitics to it from the

resistor. Is the can grounded, guarded, or isolated? Could there be

significant leakage current into the can? Could the can be filled with

tar or other potting material? this could give you yet another

dielectric absorption issue to worry about.

Ed

On 1/30/2022 4:59 AM, Attila Kinali wrote:

Hoi Ed,

On Fri, 28 Jan 2022 15:02:46 -0800

ed breya eb@telight.com wrote:

I'm not familiar with the 3458A, so don't know how the connections are

made up front. Presuming it's working right, I would suspect the

interconnect setup. The thermal voltages and contact noise may be the

main problem, especially using any sort of banana plugs.

These are not "any sort" of banana plugs. These are low-EMF from Pomona.

I doubt that wires would perform significantly better. But it's worth

a shot.

Put the

source current and high sense on one piece, and the low source and sense

on the other. In operation, the Kelvin connections tie each twin lead

pair together at the resistor, so even crappy insulation won't matter.

This I doubt. The effect I am seeing looks awfully like what I would

expect from a settling effect that takes a few seconds. And dielectric

absorption is one of those that are exactly in that time-range.

Before changing anything around, a little experiment may shed some

light. Instead of doing resistance measurements, set it to measure the

voltage on the resistor, leaving the whole setup as it was. In the most

sensitive ranges, with all those digits, I'd think you'll see the

effects of the input bias current, the thermal voltages, and some

resistor noise. The thermals should be easy to spot - just puff some air

at the connections, or wave your hand around.

That's a good idea. I'll set it up next.

Attila Kinali

Hi Attila,

I got to thinking some more about the DUT, and what's inside, and the

parasitics. I found ref [2] that you showed in the OP, about the HP

resistance standards. It's very informative, covering a lot of the

construction details. One thing that struck me is the discussion of

transient performance beginning on page 12, noting that chemical

contamination in older (non-HP) types is known to cause an

electro-chemical cell effect that can last for many seconds. I think you

said your resistor is an old type, similar to the HP ones. I wonder if

maybe this is the cause of trouble.

To eliminate all possible DUT problems, I'd suggest setting it up with

just a regular, medium precision 10 K resistor, like a T9 with wire

leads. For quick, temporary use, you can scrape off the lead plating

down to bare copper, then tightly twist the lead and copper wires to the

3458A, then crimp a splice lug on to crush them together for a gas-tight

seal. Even a (steel-insert) wire nut will do to hold it together for a

while, as long as there's good Cu-Cu contact between all the parts. Then

you can suspend the little DUT up away from everything, and mostly

eliminate the parasitics, packaging, and other issues. If it works with

this, but not the original DUT, you'll know what the deal is.

Ed

Hello Attila,

Any improvement on your 3458A results? I've got L&N 4040-10k resistor

and logged it for a bit last night. This standard was just random ebay

special, nothing fancy.

To mitigate tempco standard was placed in peltier active air bath,

programmed at +23.00°C.

Connection to DMMs front terminal was done with 4-conductor PTFE 1 meter

long shielded AWG18 cable with bare CuTe spade forks. Guard terminal is

floating and not connected at the resistor end.

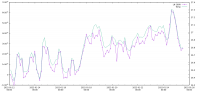

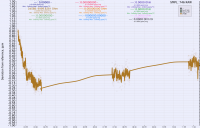

Attached a plot with 725 samples acquired. Initial slope was due thermal

settling of the resistor after placement in air bath chamber.

Dots on plot indicate individual samples. Scale is in ppms from

9999.8270 ohm value. Horizontal time scale is 30 minutes/div.

Overall noise of readout is within ±0.35ppm peak to peak.

My 3458 configuration function was:

def init_inst(self):

# Setup HP 3458A

self.inst.clear()

self.inst.write("PRESET NORM")

self.inst.write("OFORMAT ASCII")

self.inst.write("TARM HOLD")

self.inst.write("TRIG AUTO")

self.inst.write("AZERO ON")

self.inst.write("LFILTER ON")

self.inst.write("NRDGS 1,AUTO")

self.inst.write("MEM OFF")

self.inst.write("END ALWAYS")

self.inst.write("OHMF 10E3")

self.inst.write("OCOMP ON")

self.inst.write("NPLC 50")

self.inst.write("NDIG 9")

self.inst.write("DELAY 1") # 1 second delay to mitigate OCOMP

accuracy issue due DA

RAW data file is also available:

https://xdevs.com/datashort/hp3458b_ln4040_10k_minibox_23c_test1_feb2022.dsv

Hope this helps.

BR,

Illya

On 1/30/2022 8:41 AM, Attila Kinali wrote:

Hoi Illya,

On Fri, 28 Jan 2022 20:22:56 -0500

Illya Tsemenko illya@xdevs.com wrote:

First off, are you confident that your 3458A is properly working and has no stability

issues due to A3 U180 drift?

Yes. My meter has not been in use for quite long, so first thing I did was monitor

what CAL 72 did. As you can see from the first plot, it took about half a year of

continuous running until it settled. Since new year, CAL72 has moved up by a ppm.

So I guess that the ADC board is ok.

As for your APER vs NPLC timings and noise. Keep in mind that when you select NPLC larger

than 10 meter internally configure ADC to perform not single but multiple conversions

with max NPLC 10, and then average out readings before giving to user. So running NPLC

100 (typical sweetspot for 3458s) meaning that meter makes 10 internal readings and give

you average of those as result. OCOMP and Delay is also applied after -each- reading, so

you get longer than expected acquisition times.

Yes. I know. That's what explains the sqrt(5) difference in noise between APER 1 and

NPLC 50. That also explains why NPLC is more succeptible to the settling I see than

APER is, because NPLC switches every 200ms. I.e. if the settling isn't over after DELAY,

NPLC will see the residue, while APER will give it an other 800ms to settle and give

the average over that period.

I join the suggestion to ditch banana connectors altogether and use direct spade to post > wiring.

I am not convinced that it's EMF. At least not caused by the cables.

I measured an 100Ω resistor earlier and it did not show anything like this

(measured with NPLC 100, OCOMP OFF, AZERO On and whatever the default DELAY is).

If anything, if EMF was a problem it should be 10 times worse with 100Ω as

the voltage applied to the resistor is 1/10th than with 10kΩ. But as you can

see from the first plot, the 100Ω shows only the ~6.7ppm/°C tempco I would expect it to.

And once this tempco is removed, the combined temperature correction and measurement

uncertainty is about 0.5ppm.

Meanwhile, the 10kΩ (measured with APER 1, DELAY 2, OCOMP On AZERO Once) shows jumps

of >1ppm between measurements. So much that, with the little data I have, I wouldn't

even attempt to calculate a temperature coefficient. The cables are the same, so

the EMF should have the same effect (with the excpetion of the resistor side, that

is now of course different).

My guess is, that most of this uncertainty is from the settling I am seeing, which

I can't really figure out. I think it is dielectric absorption, but I am not sure.

Unfortunately, I don't have PTFE cables at hand.

Do you have any timescale data plots or CSV files with your setup? You should see flat

nice and steady data with specified meters noise, without random jumps or excessive

noise. If there is large slope over time, then its good idea to check temperature

stability. If your resistor has 10ppm/K TCR then to get 1ppm stability you must maintain

environment within ±0.05C. That is not trivial without airbath chamber on any decently

long timescale (hours).

Yes. I looked at the 200 measurements of each run and they are, up to noise, flat.

The noise is also pretty well Gauss distributed, at least for the 100Ω case. For

the 10kΩ case I see a slight e^-t slope at the beginning, but only if I correlate

multiple measurements together, Otherwise it's below the noise. (With APER 1 DELAY 2)

I have found some old test with 3458A with 10kOhm measurement, while ambient temperature allowed to go crazy:

https://xdevs.com/sl935_10k_sep/

One can see that loosing 10ppm due to temperature excursions is not hard at all, even with <0.1ppm/K resistance standard (Fluke SL935 has internal oven for resistor elements).

Ah.. Ok. So you have some effects. But at least it seems to be mostly temperature related.

Your noise is about a factor 10 below what I see and is where I would expect it to be.

If you have another more stable standard, that would be good alternate check. Sometimes

these decades long standards go bad too (from user abuse or mishandling) and become

unstable no matter what.

Unfortunately not a 10kΩ standard only a 100Ω and a 1kΩ. I will see what these show

with the new settings I have.

Attila Kinali

volt-nuts mailing list -- volt-nuts@lists.febo.com -- To unsubscribe send an email to volt-nuts-leave@lists.febo.com

To unsubscribe, go to and follow the instructions there.

Moin,

On Wed, 9 Feb 2022 00:50:58 -0500

Illya Tsemenko illya@xdevs.com wrote:

Any improvement on your 3458A results?

A bit. I now know what isn't the cause: The cable and EMF.

I found some silver plated, PTFE insulated AWG 30 wire (AlphaWire 2841/1)

and substituted it for the Pomona leads (Yes, not ideal, but that's the

only PTFE insulated wire I could find).

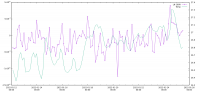

I did the same run of different NPLC, APER and DELAY settings as before

and the numbers are virtually the same. Additionally I also did a run with

APER 1 and larger DELAY numbers to see how that changes things (plot attached)

On some more long term measurement, the behaviour looks virtually the same.

There is no change that wouldn't be within the noise of the measurement.

I also covered everything in cardboard to shield it from all air currents.

While this inproved my temperature readings quite a bit (noise went down by

a factor of 5-7), it did not change the ohm reading noise at all (again,

all within noise/uncertainty).

But things are slow as the whole thing needs hours to stabilize. So each

time I change anything in the setup or the way how I measure, I let it

run for a couple of days to see what it did.

I've got L&N 4040-10k resistor and logged it for a bit last night.

This standard was just random ebay special, nothing fancy.

Coincidentally, that's the same type of resistor I am measuring.

To mitigate tempco standard was placed in peltier active air bath,

programmed at +23.00°C.

I whish I could do that as well, but my current budget does not allow

to buy a commercial air/oil bath and fire regulations prevent me from

using a home-brewn one.

Overall noise of readout is within ±0.35ppm peak to peak.

That's about 1/3 of the readout noise I have for the same settings.

My current working hypothesis is, that the resistor has some significant

temperature gradient/change based behaviour, which would explain some of

the large jumps I see, which seem to be always around when temperature was

changing quickly (as in faster than 0.01-0.02°C/h).

I will further investigate and report back once I have a better understanding

of what is going on.

Attila Kinali

--

The driving force behind research is the question: "Why?"

There are things we don't understand and things we always

wonder about. And that's why we do research.

-- Kobayashi Makoto